Pipe beveling is a crucial process in various industries that involves shaping the edges of pipes for welding or joining purposes. In recent years, the utilization of pipe beveling tool has gained significant popularity due to their ability to enhance efficiency and precision. This article explores the numerous benefits of these tools and how they contribute to streamlined operations and improved results.

-

Enhanced Efficiency

Pipe beveling tools revolutionize the efficiency of pipe fabrication and installation processes. By automating the beveling process, these tools significantly reduce the reliance on manual labor, resulting in substantial time savings. Modern pipe beveling tools are equipped with advanced mechanisms that enable workers to swiftly and accurately complete beveling tasks, ultimately boosting productivity levels.

The ability of pipe beveling equipment to do away with secondary processes such as grinding or deburring is one of its main benefits. Traditional beveling techniques sometimes include additional procedures in order to produce exact and smooth edges, which can be labor- and time-intensive.

-

Improved Precision

In pipe fabrication, achieving accurate and precise bevels is crucial to ensure a seamless fit and optimal performance of the pipes. Pipe beveling tools play a pivotal role in delivering improved precision throughout the process.

These tools are designed to provide precise and consistent bevels, ensuring that the edges of the pipes are shaped perfectly for welding or joining operations. By eliminating irregularities and uneven edges, pipe beveling tools enable welders to create strong and leak-free connections. The precise alignment of pipes during the beveling process translates into seamless and secure joints, minimizing the risk of leaks or structural weaknesses. By prioritizing employee well-being, pipe beveling contribute to a safer work environment.

-

Versatility

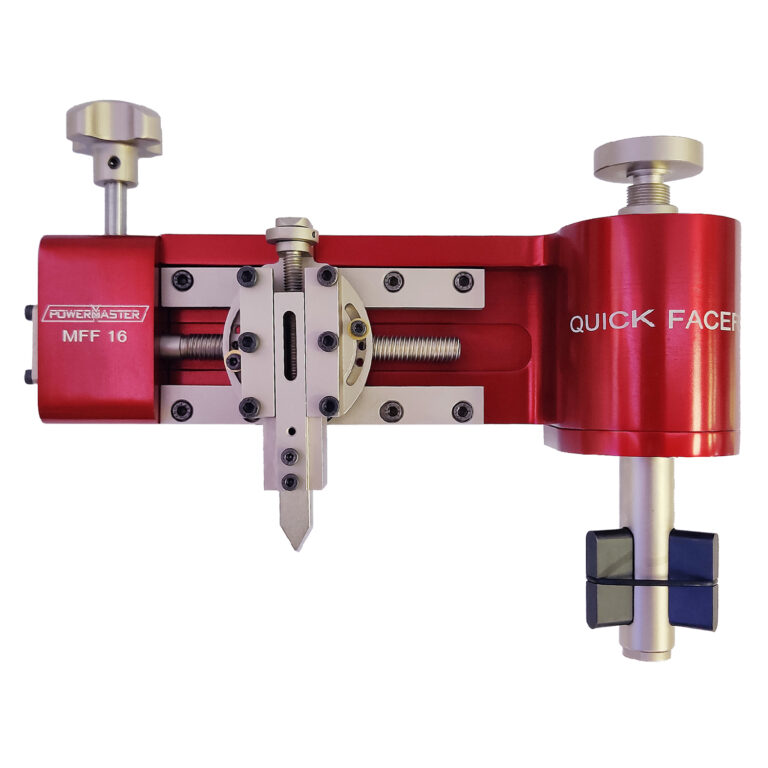

Pipe beveling tools come in a variety of designs and configurations, catering to different pipe sizes, materials, and beveling requirements. These tools possess versatility in their application, serving both large-scale pipelines and pipes of smaller diameters. They can effectively handle various pipe materials such as steel, stainless steel, aluminum, and others. Their adaptability makes pipe beveling tools suitable for a wide range of industries including oil and gas, construction, and manufacturing. This ensures accurate and effective results for any application.

-

Worker Safety

Manual beveling processes can be physically demanding and pose potential risks to workers. The use of pipe beveling tools significantly reduces the physical strain on workers by automating the beveling process. Operators can operate these tools with ease, minimizing the risk of injuries such as strains, cuts, or abrasions. Moreover, modern pipe beveling tools are equipped with safety features, including ergonomic handles, guards, and shields, further enhancing worker safety. By prioritizing employee well-being, pipe beveling contribute to a safer work environment.

Conclusion

The benefits of tube installation tools manufacturer cannot be understated in industries reliant on efficient pipe fabrication and installation processes. By enhancing efficiency, improving precision, offering versatility, and ensuring worker safety, these tools play a crucial role in streamlining operations, reducing costs, and delivering high-quality results. Embracing pipe beveling can help businesses stay competitive and achieve optimal productivity in today’s demanding industrial landscape.